The Toyota Mountain Rider wheels

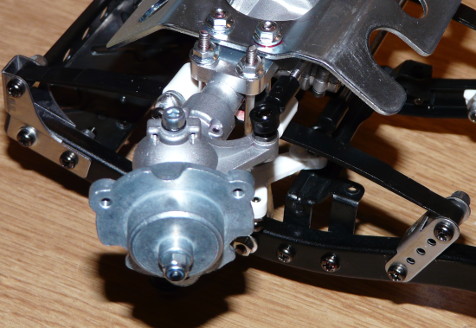

In the previous chapter, we saw the 3 Speed chassis specific wheel hubs. Just a reminder:

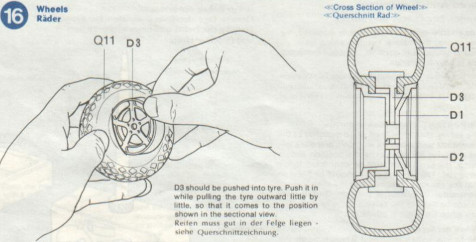

Now, here are the wheels viewed from the outside and the inside:

See? No hex as we are used to: instead, 3 screws are used to fix the rim to the wheel hub. This allows to hide the usual wheel nilstop nut inside the rim, more precisely, the wheel nut is located on the wheel axle, the whole thing being hidden by the rim with a molded fake hub in its center. Apart from this, the rim is made out of chromed plastic and you will need to file the chrome on the parts in contact with the tire rubber (otherwise, the tire won't glue to the rim).

As for the tires, they use the same pattern as the 1986 Blackfoot. However, the tires of the Bruiser / Mountaineer (and re-released versions) are made of a much harder compound: they will work just fine for shelf display and to run on asphalt (surface on which they will probably last forever). But if you think about running your model on trails where traction is required, the stock tires will soon show their limits.

As a conclusion on these wheels, one more detail: these chromed rims with fake hub are the exact replica of the 1992 Mountaineer rims. These same rims are supplied with the 2012 re-release Bruiser too, but the original 1985 Bruiser was supplied with slightly different rims that we will see next.

The original Bruiser beadlock rims

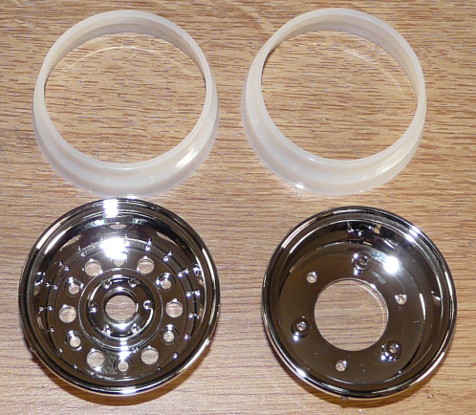

Beadlock: these rims are made of 3 different parts, one ring is placed inside the tire and 2 side “plates” are bolted together. In practice, the inner lips (or beads) of the tire are squeezed between the ring located inside the tire and the side “plates”. This system is mainly used for off-road vehicles because it allows to run tires with low pressure, that is under-inflated tires: especially in the mud, in the sand or on any soft surface, an under-inflated tire will offer an increased surface of contact with the ground because the tire will flatten instead of sinking into the soft surface. By flattening over the surface, the grip of the tire is improved. This system is used in RC, in particular in the crawler and trail disciplines that require a lot of grip, but the system is also used on full-sized vehicles (for tailing of course, but also for races in dunes or on some military vehicles).

On the 1985 original Bruiser, the rims were of beadlock type and Tamiya re-released them too under the reference 54414 R/C 4x4 Vehicle 4-piece Wheels (pair):

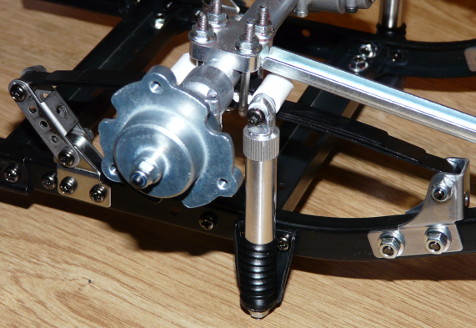

So the system is what was previously described, here using Proline Flat Iron tires, the only tires I found with overall dimensions close to the stock Bruiser / Mountaineer tires. By the way, you can notice the rims lack the center fake wheel hub. Other point of interest with beadlock rims, you do not need to glue the tire: this allows to easily swap tires and to re-use the rims when the tires are worn.

So, beadlock rims are another innovation Tamiya brought to RC with the Bruiser in 1985. Wait... may be not, they may have been seen before, quite long before actually:

Long before the Bruiser, there was the XR311 FMC Combat Support Vehicle in 1977 !

Then the SRB used them too in 1979, the first 3 Speed models too (Toyota Hilux and Blazing Blazer in 1981-82) and even the Grasshopper / Hornet (1983-84) were equipped with beadlock rims, before the 1985 Bruiser. So, if the Bruiser did not introduce the beadlock rims in RC, to my knowledge, Tamiya did, probably for scale realism reasons because the full-size American Army XR311 FMC was using them (as well as other military vehicles).

Now my Mountain Rider is equipped with boots to climb mountains, so let's build one of the most iconic mechanical system in the RC history: the legendary 3 Speed gearbox.