The Dyna Storm gearbox

In addition to the dampers we'll see further on, the Dyna Storm is also renown for its slipper clutch. For more details about what is a slipper, please read the article about my Porsche 935 Martini.

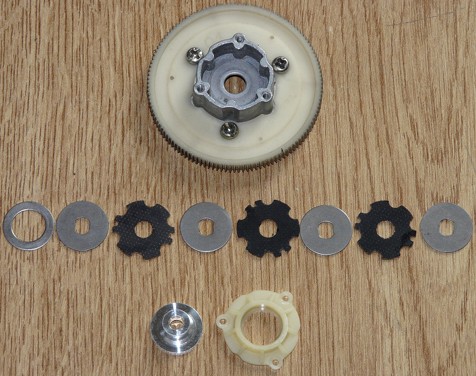

In 1991, the Super Astute had abandoned the Astute's ball differential but gained Tamiya's first slipper clutch. One year later (so about 2 years after Associated's revolutionary Stealth transmission), Tamiya designers improved their first try and reintroduced the ball differential on the Dyna Storm:

Multi Disc Clutch exploded view

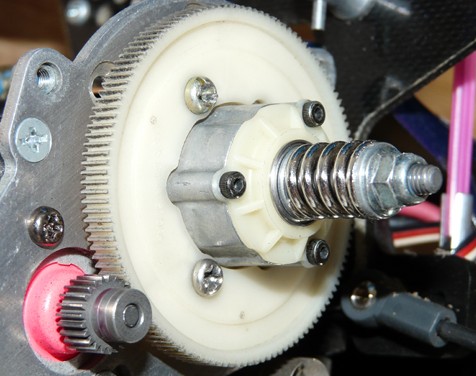

Multi Disc Clutch installed

Difficult to say whether this improved system is better than the Super Astute's TTC since I don't own this model to compare: it should be better even if my researches did not unveil only positive comments about it. Anyway, I found that getting the right setup both on the slipper clutch and the ball differential was not an easy task.

The Dyna Storm dampers

Since the Fox in 1985, Tamiya supplies reliable and efficient hydraulic dampers on many of their models. Once yellow colored, the famous CVA dampers (Constant Volume Adjustable) still exist, the most obvious difference being they are now black. However, Tamiya engineers never stopped working on these elements to develop new more efficient units until the quite recent TRF dampers we now have (for the luckiest of us).

So first, let's see how current CVA dampers work: on purpose, I chose one of my Fox dampers for this explanation, but any modern black CVA from any modern model would suit just fine too. My vintage attitude ![]()

- 1985: CVA Dampers

Click to enlarge

First you fill the damper tank with oil, you purge any air bubble left and you place a joint seal that will keep the oil separated from the air contained in the damper cap. The damper contains two elements which density (thus resistance) is different: on one side, the more or less viscous oil through which the damper piston travels, and on the other the air above the joint seal. Under the piston pressure, the oil resists and pushes onto the joint seal that will compress the air from the damper cap. The density of these two elements being different, the result is a stiffer dampening effect when the piston thrust is brutal, and a softer dampening effect when the piston pushes smoothly.

With this damper, you'll notice the piston is one-piece with the rod: the piston head is not perfectly round to leave some room for the oil, but you can't adjust the oil flow. Some time later, Tamiya will introduce removable plastic piston heads with one or several holes allowing to adjust the oil flow.

Now let's have a look over the Avante dampers, introducing the first consequent evolution in 1988:

- 1988: Avante Hi-Cap Dampers (v1)

Click to enlarge

On the Avante, the damper built and work principle are the same as the old yellow plastic units. The oil tank is made of anodized metal and the lower cap includes a Teflon guide to improve the piston rod traveling.

However, you can't miss the spring shape: not cylindric, the lower narrow side is stiffer than the upper larger side. This technique provides a progressive dampening, stiff at the beginning and softer afterwards: this dampening technique is the best choice for "potholes" tracks.

- 1989: Egress Hi-Cap Dampers (v2)

Click to enlarge

In 1989, The Egress Hi-Cap Dampers didn't look like bringing much evolution at first sight, apart from moving back to a more classic cylindric spring and showing new spring stays. As for the retainers, they look like they were inspired by the famous Kyosho red dampers the Optima made so popular in 1985. However, the Hi-Cap Dampers version 2 do feature an evolution as important as discrete: a small hole in the upper damper cap (the above picture in picture). This small hole makes a big difference: on the previous Avante Hi-Cap Dampers and on CVAs, the air was confined between the oil seal and the damper cap, meaning it was pressurized when the damper piston was pressurizing the oil. As soon as the pressure stopped, the air expanded again to regain its normal volume: this automatically made the piston rod move back, so the damper to decompress partially. You can easily reproduce this: take any classic CVA damper correctly filled with oil and closed, remove the spring and push the piston rod to the max. As soon as you release it, the piston rod will naturally move back about 5mm.

The Hi-Cap Dampers version 2 work differently: when the piston moves, pressure is transfered onto the oil seal forcing the air in the damper cap to escape through the small hole in the damper cap. As soon as the damper decompresses again, the pressure on the oil seal stops and it moves back to its natural position, sucking air back into the damper cap. The first consequence is that the air doesn't compress anymore into the damper cap, so it doesn't force the piston rod to naturally move back when pressure stops, unlike what happens with classic CVAs. The second consequence is that the piston only fights the oil viscosity (according to the oil viscosity and the number of holes in the piston). The result is an even softer, and most of all smoother dampening than with previous damper generations.

- 1992: Dyna Storm Sleeved Dampers

Click to enlarge

The Dyna Storm Sleeved Dampers introduced a radical evolution: the oil seal keeping air apart from oil disappeared, as well as the hole in the damper cap. The manual recommends to fill the oil tank leaving 1mm of air at the surface before closing the damper. For every damper based on the CVA principle, the air from the damper cap has to be kept apart from the oil in the tank: it is the opposite with the Dyna Storm Sleeved Dampers. Here, the oil tank purposefully contains air in suspension: when the piston rod pushes, the mix of air and oil get through the piston head holes to deliver a very smooth dampening. If the tank contained only oil, the oil flow provided by the sole piston head holes wouldn't suffice because oil (even fluid) is a very thick element.

You will also notice a white cylinder: it goes inside the oil tank. It is Teflon-coated in order to provide the best possible sliding for the piston head (Teflon is a lot smoother than the inner tank metal). The piston rod is also guided by a (white) Teflon joint you can see at the bottom of the tank. You can also notice the piston head is the same as the classic CVAs and the (black) seal that was added below the damper cap screw thread in order avoid oil from leaking.

In practice, you need to manually "start" a Sleeved Damper when it wasn't used for a long time by forcing compression: naturally, the air tends to separate from the oil and the "start" recreates the air/oil mix. When working, these dampers make a squeezing noise: this is normal, unlike if you hear the same noise from CVA dampers since it means air got into the oil (meaning oil leak or oil seal to be replaced).

As for the different dampers efficiency, Hi-Cap Dampers (Avante / Egress variants) and Sleeved Dampers undoubtedly work better than classic CVAs, and among the last, the modern black units are more efficient than their yellow predecessors. However, deciding between the Hi-Cap (whatever variant) and the Sleeved dampers is more delicate: the Hi-Cap are said to be softer than the Sleeved but more prone to leak (especially at the damper bottom joint). To be honest, I saw no difference between the two: both are very smooth and provide excellent dampening.

First runs with the Dynastorm

As soon as I could, I went to the track or the first runs. Once in its element, the Dyna Storm looks very aerodynamic thanks to the bodyshell smooth and precise silhouette, making the model look very elegant:

In fact, many consider the Dyna Storm as one of the most beautiful 2WD buggies from the modern era: I share this opinion, especially compared to current productions. Check this classy profile:

Once on the track, the Dyna Storm feels very well balanced, despite a serious under-steering character. In bumpy sections, the Sleeved dampers work amazingly well, providing the chassis with an excellent stability: in terms of efficiency, although a direct comparison is difficult, I think they are performing much better than the classic CVAs you find on many Tamiya models. In fact, they feel so close to the modern TRF dampers that I wouldn't dare saying which ones are the best, despite the 20 years gap of technological evolution between them.

One surprising aspect is the transmission noise: at the first test run, the differential was too loose and I mis-built the slipper clutch. For the second test run, I had thoroughly rebuilt both the differential and the slipper clutch, but the transmission still sounded the same. In the end, this is normal and it sounds very much like another model of my friend David RC 4 Old Nuts: his TRF201, the one that can be considered as the Dyna Storm grandson.

Driving the Dyna Storm feels pretty easy, just like with a TRF201 or most modern racing buggies: the chassis and suspension are performing so well that the driver suddenly feels his driving skills reached new skies when it is mostly due to the model "absorbing" driving mistakes. With a less competitive chassis like my Sand Viper's DT-02, the driving skills immediately show on the model handling.

However, even if the Dyna Storm encourages to push the throttle, the driver should always keep in mind that this model is fragile. The front drivetrain is the most to worry about, especially the C-hubs (and the front arms, to some extend), as well as the plastic plate on which the damper stay is bolted. Finding spare parts is very difficult (and expensive), but if you can find them, get the TR-15T's parts since they are made of reinforced plastic (use the manual to find the references you need).

As a conclusion, the Dyna Storm is a very interesting model to have since it ends the dynasty started with the Astute in 1989. Both for its technical aspects and look, this model is a demonstration of Tamiya's engineering skills at the beginning of the 90's. Of course, the Dyna Storm no longer can compete with current productions, especially on material strength, but its performances and handling on the track are not totally outdated yet.

Thanks to its great design, driving the Dyna Storm is truly amazing: the buggy perfectly responds to the commands and the handling is absolutely great, especially due to the amazing suspension efficiency. In fact, the driver needs to always keep in mind that the Dyna Storm is now rare and quite fragile: after a few laps, it becomes easy to get more optimistic since the Dyna Storm seems more than ready to go much faster, too fast considering its age.

Related articles