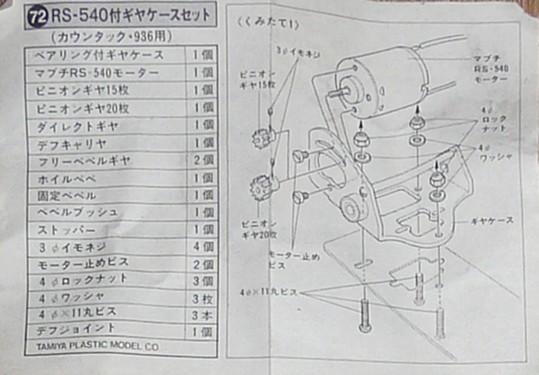

The Martini Porsche 936 Turbo chassis

This section is shared with another article to be soon published.

However, everything described here does apply to the Martini Porsche 936 Turbo because the chassis is the same.

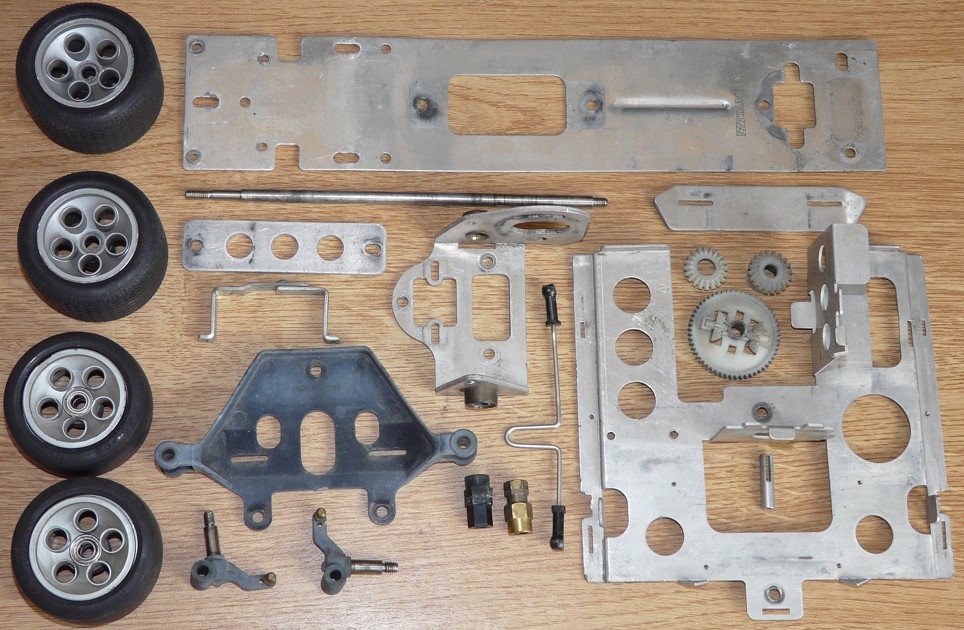

First of all, full chassis disassembly before cleaning:

For cleaning, I tested a new product on metal parts that worked quite well: Pierre d'Argent (silver stone: don't know if it is sold outside France). It is not a stone since it is clay, and there is no silver in it. This powder cleans, de-oxidizes and polishes plastics and metal without scratching the surface.

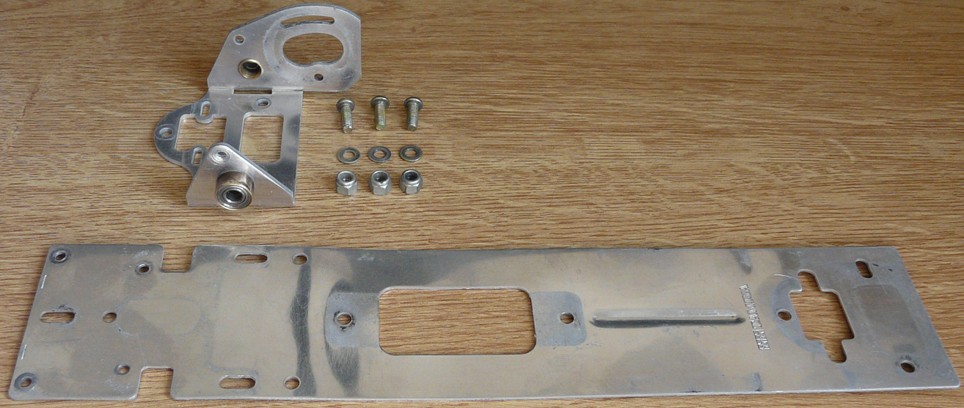

After cleaning, let's begin the assembly starting with the rear pod:

The motor mount is not the original unit since it can hold a Mabuchi 540 when the kit was supplied with a Mabuchi 380. In fact, what we have here is the SP72 option for kits 58005 and 58006:

You can notice this optional motor mount still places the motor on the right side of the chassis, right where the 380 motor is located on the original version, whereas the motor is located on the left side of the chassis on the chassis CS versions that will follow a few months after. You can also notice that this motor mount, as well as its reversed CS version, are both supplied with ball bearings.

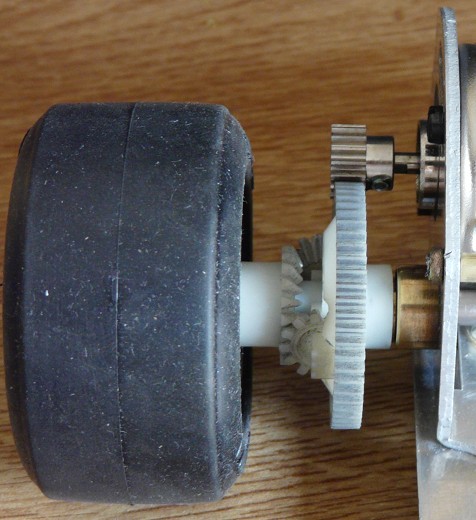

Next step of the assembly is the bevel gear differential:

Differential fitted on the wheel axle and then on the motor mount:

Rear pod full view:

Yes, you do see brand new tires here: more about them later ![]()

Next step of the assembly: the bodyshell retention system.

Overall, it is quite simple: the bars with hooks are to be fitted onto the bodyshell. To install the bodyshell on the chassis, the bar hooks have to be inserted into the chassis holes and then secured using the catch pin. On my chassis, the hole to secure the font of the bodyshell with the catch pin is broken (second photo, on the right). After a few tests, this is not a problem when running the model as it is meant to be run considering it age and fragility.

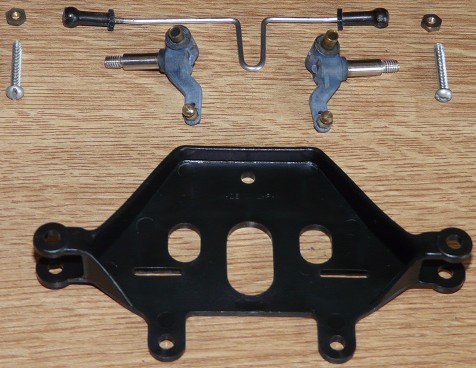

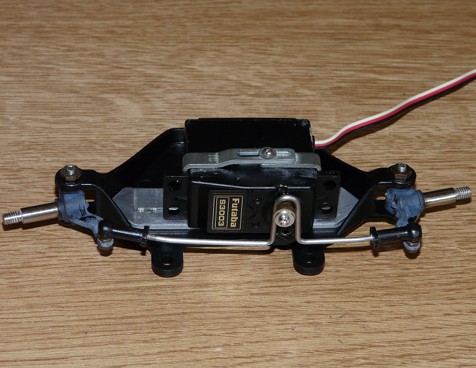

Now let's go for the front drivetrain assembly:

This is one of the main differences between my chassis and CS versions: this part was considerably reinforced on the CS versions by using metal instead of plastic. I swapped the arms/servo plate with a brand new part I had in my stock because the plastic had whitened due to its age (this is the exact same part as on the Martini Mk.22 Renault). Same problem for the uprights but I had to stick with the parts that came with the chassis (also shared with the Martini Mk.22 Renault).

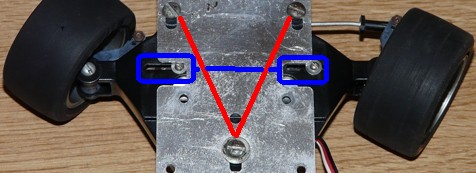

The front drivetrain is now finished. It allows some interesting setup capabilities:

Circled in blue, the screws fixing the steering servo can slide sideways: this is the steering trim adjustment that period radios were lacking (except very high end period radios, perhaps). In red, the 3 screws attaching the front drivetrain to the rest of the chassis: they can also slide from front to rear, allowing to adjust the wheelbase to match the bodyshell. Here again, you can see healthy tires: be patient, you'll read more about them next.

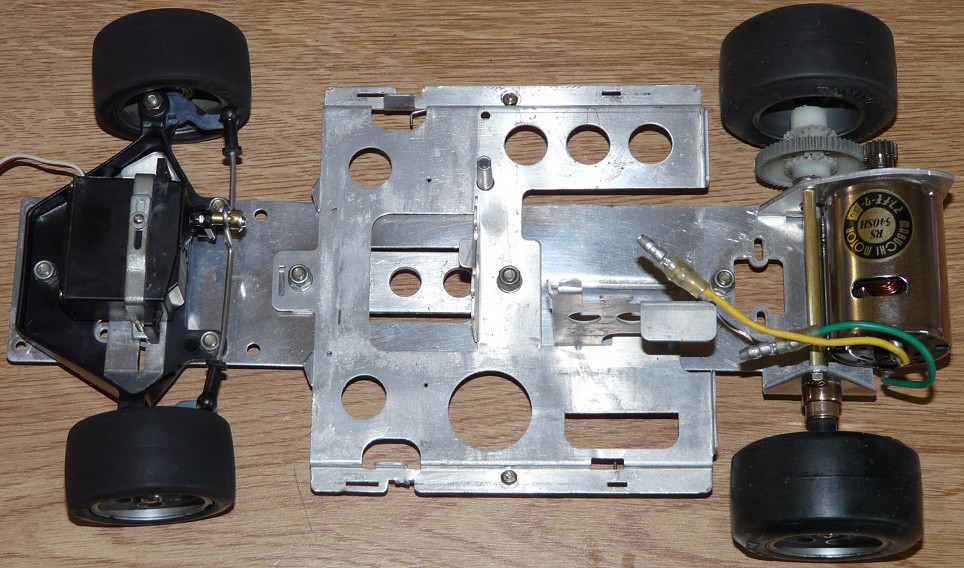

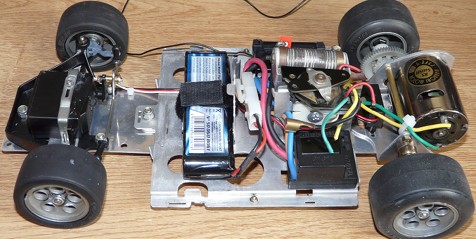

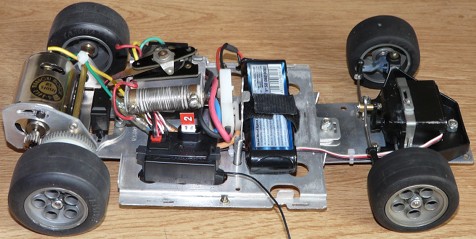

Now, the chassis is almost finished:

Installing the electronics also means solving the battery question since standard 7.2V sticks are too long to fit in the bodyshell width:

The electronics are a standard 27MHz radio system and a TEU-101BK speed controller. The period mechanical speed controller is not connected, but I did everything I could to keep it for aesthetics. The power supply is an nimh mini stick pack made for TamTechs (my Porsche 935 Martini or my Mini Hornet).

We are done with the chassis: now let's talk about those tires.