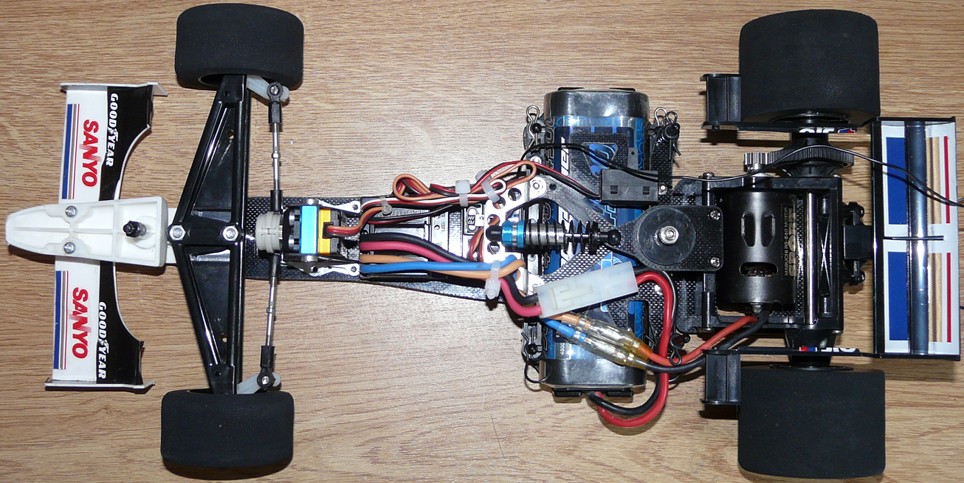

The F103RS chassis of the Williams Renault FW18

With their F103 chassis, Tamiya introduced several major improvements over the previous F102, from the chassis plate to the front drivetrain, the differential and the suspension.

Let's start with the chassis, starting with the F102 followed by the F103:

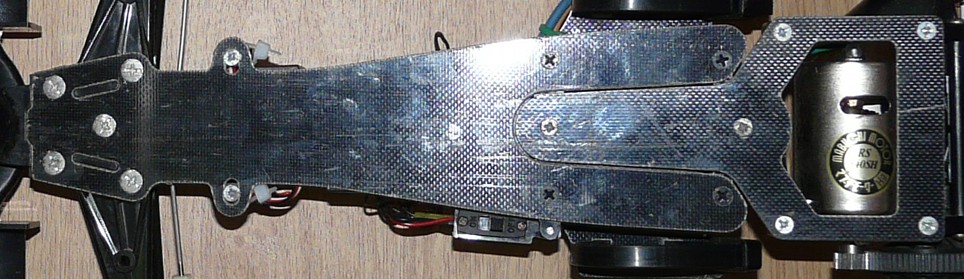

Obviously, the F103 is narrower than its predecessor, either at the front where the front arms are bolted or at the servo location, the battery tray and even the rear end T-Bar shape (the T-Bar is the part located under the motor, heading forward inside the chassis plate). Moreover, even if photos can't show this, the F103 chassis is much stiffer than the F102's: this is a radical change compared to previous versions of the chassis dynasty started 7 years before with the Road Wizard.

By narrowing the chassis, especially at the front, Tamiya designers intended to improve the suspension efficiency. As the chassis is narrower, the front arms are longer and this helps improving the overall suspension precision and efficiency. The difference in front arms length is depicted hereafter:

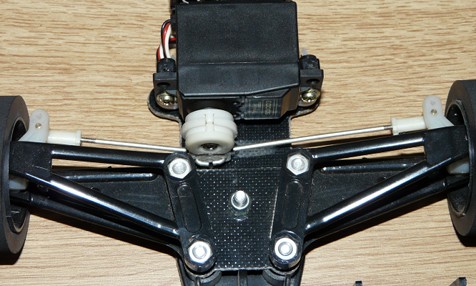

F102 front drivetrain

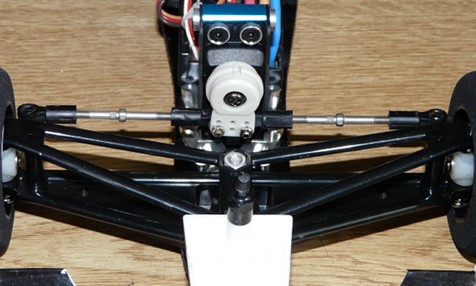

F103 front drivetrain

You can also notice that reducing the chassis width implied another major evolution: the steering servo is now placed vertically, allowing to perfectly center it in between the wheels and the chassis for a better weight balance (despite the higher center of gravity). On my model, the servo stay is a carbon structure (3Racing part): in stock form, the servo has to be double-sided tapped against a vertical plastic part.

The most important improvement on the front drivetrain is the simpler built: on the F102, the front drivetrain is made out of 4 parts (1 upper arm and 1 lower arm by side) held by a plate, 4 screws and nuts. On the F103, only 2 parts are used (1 upper and 1 lower part for the whole drivetrain) held by 2 screws and nuts. Apart from being simpler, the whole drivetrain is lighter due to eliminating half of the steel screws and nuts.

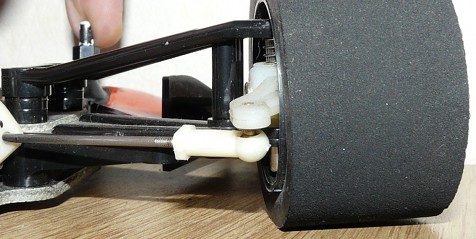

Next improvement, the front wheel suspension: on the F102, the spring is located on the lower side of the wheel axle, sandwiched by the upper and lower arms. On the F103, the spring was moved below the lower arm:

F102 front suspension (view from behind)

At full load

F103 front suspension (view from the front)

At full load

The advantage of this solution is to move the spring weight at the lowest (even if we're talking about a few grams only), but mainly to make spring changes easier. On the F102, you need to disassemble the wheels and the arms to perform this operation. On the F103, you only need to remove the wheel and the C-clip holding the spring. In theory. When building the front drivetrain, I found this operation rather complicate and unfriendly (you need to compress the spring while fitting the C-clip at the same time), but this may be a question of practice.

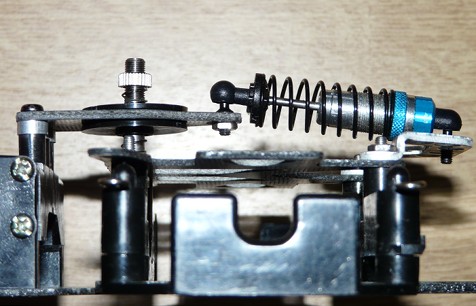

Next major improvement, the rear drivetrain suspension was radically changed. The F102 chassis features the same system the Road Wizard's introduced back in 1986:

With the F102, likewise its predecessors, the rear pod movements are controlled in two different ways depending on their kind:

- longitudinal movements:

these are the rear pod movements oriented from the rear to the front of the chassis (and reverse). They are controlled by the damper joining the rear pod to the battery stay upper deck. - side movements:

these are the rear pod movements from left to right (and reverse), typically those occurring in corners (also called chassis roll) that directly influence the front drivetrain steering response. These movements are controlled by how strong you tie the T-bar screws to the battery stay.

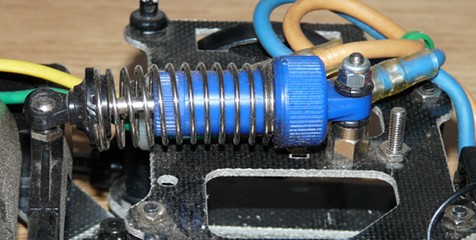

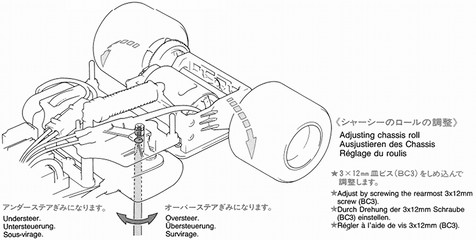

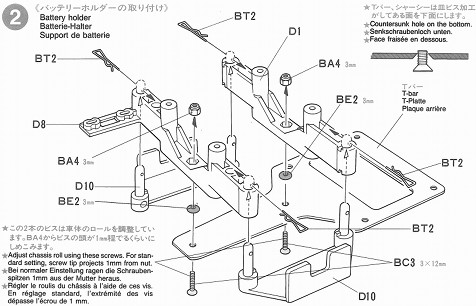

With the F103 chassis, the system was totally changed:

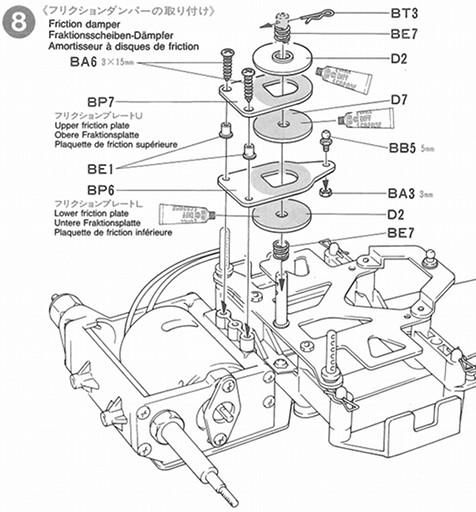

On the right side manual excerpt, you probably recognize the chassis roll adjustment through the T-Bar screws. However, the damper now connects to the rear pod through a friction plate partially acting both as a chassis roll control and longitudinal dampening. This friction plate is also the main difference between the original F103 chassis and the RS version of my model (on the right):

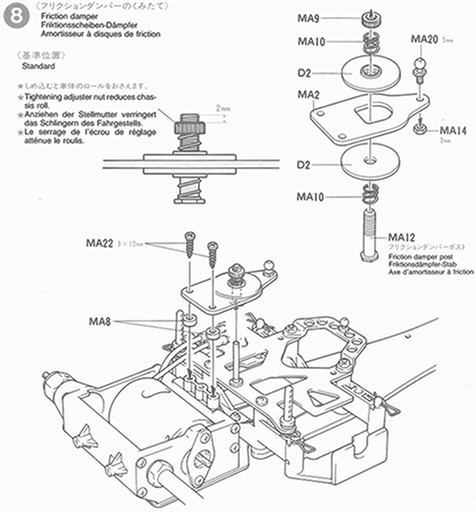

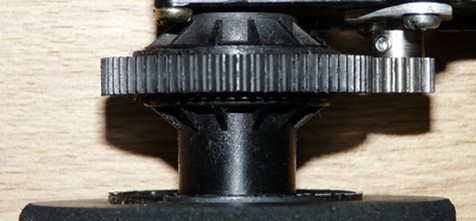

Basically, the system was simplified, from using 3 to 2 friction disks and offering a much more precise setup thanks to the adjuster nut that replaces the previous 2-position clip system. For real, the parts making the RS version friction plate system:

In concrete, setting up the front drivetrain response is made like with the F102 and predecessors, by tightening the T-Bar screws. Likewise, setting up the dampening effect is mainly made through the damper itself: these two elements determine the chassis overall handling. The friction damper settings (as well as the grease viscosity applied to the disks) mainly serve to more precisely adjust the settings to perfectly match the track conditions.

Apart from it precision, the main advantage of this solution is that adjusting the friction damper system will jointly affect the dampening and the chassis roll. Once you have found the best dampening and front drivetrain response settings, you don't need to change them since the best chassis balance was found. However, since grip and surface quality change from tracks to tracks, it is very helpful to be able to adjust both the dampening and the chassis roll in equal proportions depending on track conditions (or temperature that impact grip).

Last improvement on the F103 chassis:

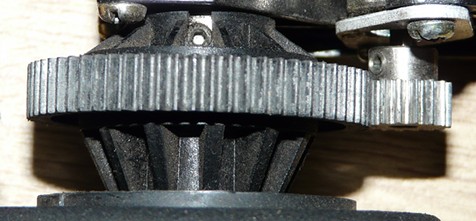

F102 differential

F103 differential

In fact, apart from the differential housings, everything else is strictly the same. Which means the differential first seen on the GroupC chassis (my Jaguar XJR-12) that was borrowed by the F101 and F102 simply received a slimming treatment on the housing side to reduce weight.

To conclude this part of the review, here's the chassis ready to run: