The Road Wizard F1 chassis

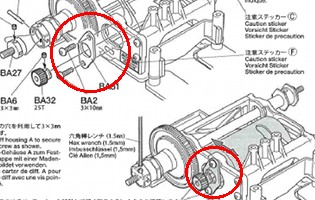

Apart from a serious cleaning, there is not much to do on the chassis. However, two specific aspects of the chassis caught my eyes as their design may explain the fragile reputation of the Road Wizard F1. The first one is located at the front drivetrain:

The front lower arm seen from below

The front upper arm

The first photo shows the arm molded to the part that make the whole nose of the model. Whenever the front wheel hits something at speed, the front arm may break and anything located in front of the steering servo is to replace. The same applies if the front wing gets broken. For racing, it is better to consider having a full front drivetrain already assembled in the spare box: on the other side, there are only 3 screws to remove to replace the complete front drivetrain. This is a very quick and easy repair at the pit stop, if not the cheapest ![]() .

.

Nothing missing on the second photo: the upper arm only has one fixing point. Of course, it is not the strong assembly you could expect but if anything were to stress the upper arm to the break point, the lower arm would already have broken. So having one or two fixing points on the upper arm is not that important: here again, the only preventive action is to prepare a spare front drivetrain.

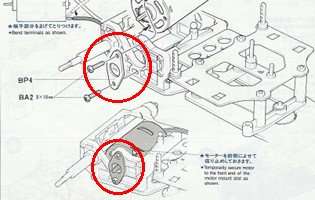

The second weak point is located on the rear drivetrain. If the front drivetrain is a logical guess based on a close look, I can prove the one on the rear drivetrain:

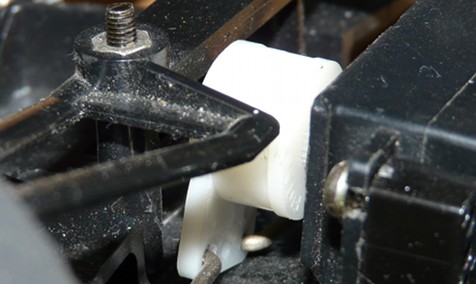

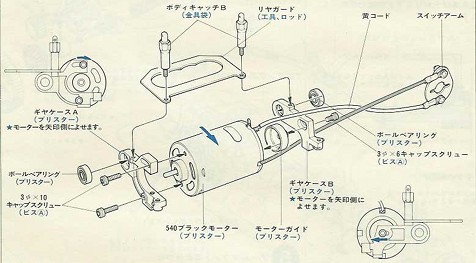

Broken motor mount

The complete motor mount part

The first photo shows the motor mount upper side and it didn't appreciate the way it was treated. Now the problem is to repair this part which, by luck, is unique to the Road Wizard F1's.

The main concern here is there's very little room to install anything. My first idea was to reinforce the rounded part of the motor motor with a metal plate that would wrap it. No way, both because fixing this plate is complicated (especially inside the inner C shaped side due to the motor) and because the few available room would make the plate be very thin, thus not resistant enough.

Next option I thought about was to mount a "column" from the motor mount lower fix point (low center on the above photo) and to fix a rounded shaped part that would wrap the motor mount upper side by the exterior. Bad idea since I couldn't imagine how to wrap the motor mount round shape and because the whole thing didn't seem to be strong enough. Also, adjustment would have required to be very precise: a loose wrapping part would have been useless, but applying too much pressure on the motor mount would have led to misplace the motor pinion on the countergear.

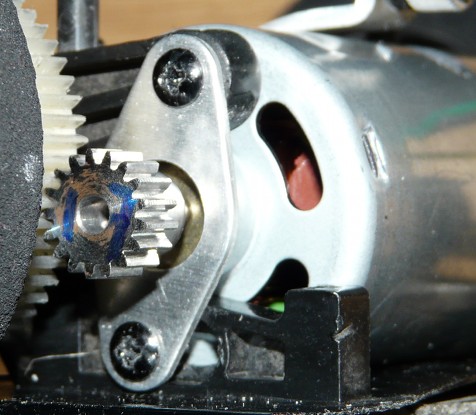

This is where advices from Vintage-RC members were vert useful: their idea was to fill the screw hole and the outer crack with two component epoxy resin. Then to re-drill the screw hole and to "import" an extra metal part used on other models (see below).

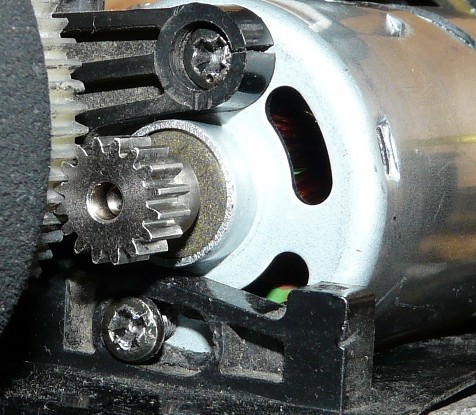

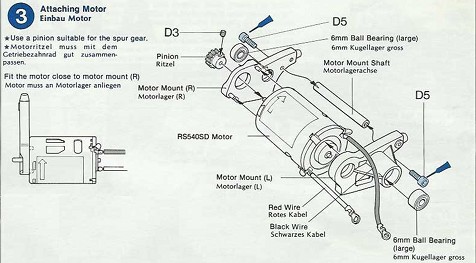

The original assembly

The final assembly

I can't be sure that this repair will resist: that's why I hunted for a new motor mount and the reason why my Road Wizard F1 will not receive more than a stock Mabuchi 540 (like all my vintage models anyway). By the way, yes, the motor pinion is a 17T: the manual only mentions the 16T despite the motor mount allowing adjustments. The Williams FW11B manual mentioning both 16 and 17T, I gave it a try on my chassis and it works. The 18T makes the gearing stiff though, so I preferred not to insist.

As I have been thinking about repairing this broken motor mount for hours, one question came to my mind: why did Tamiya designers draw this part open? After all, we're talking about one of the two motor mounting points and as such, critical points receiving constraints. Just hold a stock Mabuchi 540 and play with the trigger to figure out how the motor housing wants to rotate. So why drawing an open part? Making it closed would spread constraints over a much stronger structure.

One of my bad habits is to keep thinking to anything even when I should be focus on something: I can't help it. Here, while manipulating that broken motor mount and imagining potential repairs, I was thinking that this was not Tamiya's first attempt at Formula 1 chassis. I agree previous F1s were pretty rustic, but the last Racing Master generation being quite an inspiration for the Road Wizard F1, designers had already some experience. So I paid a visit to my manual collection for some investigations:

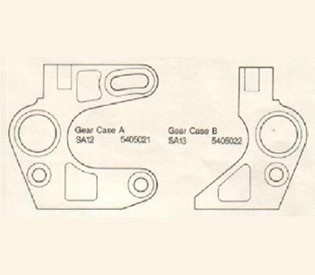

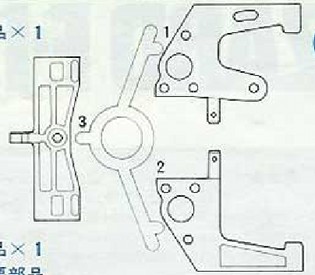

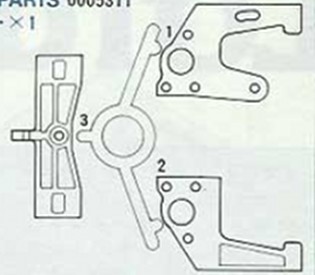

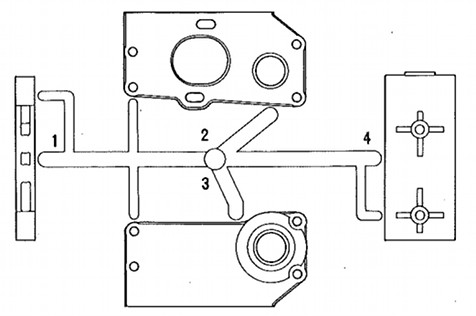

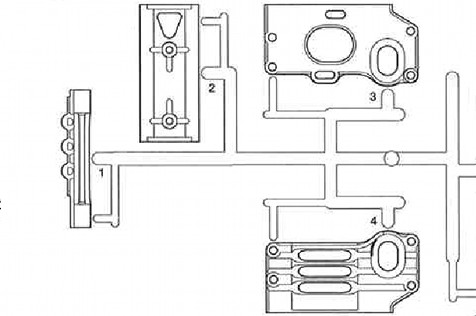

58049 Toyota Tom's 84C (1985)

58053 Road Wizard F1 (1986)

58069 Williams FW11B (1987)

Damned! All of them are U shaped (C shaped to be honest). No big surprise with the Williams FW11B since it is the Road Wizard F1 "update". So it is the last three Racing Master original design that was adapted to the Road Wizard F1.

58021 Can-Am Lola Racing Master 1 (1980)

58032 Tornado Racing Master 3 (1982)

Ah! We now know the culprit for the motor mount design: the Racing Master 3. Boo! Boo...? Well no, not boo: sorry Mister Racing Master 3.

I forgot to mention that Tamiya changed the material between the Racing Master 3/4 (Tornado/Ford C100) and the Racing Master 5/6/7: the motor mount C shape design on the Racing Master 3/4 is in metal whereas it is in plastic on the next generations... as well as it counterpart in modern Formula 1 chassis. The weakness on the Road Wizard F1 is not a design problem but the result of using a weaker material (and may be also due to changing the scale since Racing Masters are 1/12 whereas modern Formula 1 beginning with the Road Wizard F1 are 1/10).

We move on... Now let's how long Tamiya took to solve the problem:

F101 / 58084 chassis (1990)

GroupC chassis (1990)

F102 chassis (1992)

If you think you've been looking at the same 3 pictures... that's OK! The 3 chassis use the exact same part tree ![]() . The C shape design is still the same as on the Road Wizard F1. Nevertheless, we can guess that Tamiya made some changes in the plastic formula to make it stronger since I never had any problem with my Jaguar XJR-12 and my Footwork FA-13.

. The C shape design is still the same as on the Road Wizard F1. Nevertheless, we can guess that Tamiya made some changes in the plastic formula to make it stronger since I never had any problem with my Jaguar XJR-12 and my Footwork FA-13.

Now let's see the latest F1 chassis:

F103 chassis (1993)

F104 chassis (2009)

Here we are! At last, closed motor mounts... 20 years later. Again, this is all relative since motor mounts have no specific reputation of weakness on GroupC and F101/F102 chassis.

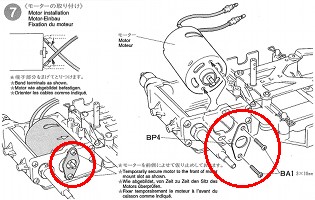

One naive question: may a little part have a huge influence on C shape motor mount resistance? Let's try with luck: a part that would have first appeared on the 58084 chassis (and GroupC) and that would be still there even on the very modern F104 chassis despite its "closed design" motor mount?

The 58084 chassis "magic" part

On the F103 chassis

On the F104 chassis

4305259 motor plate: this is the sweet name of the metal part you can find on every Tamiya Formula 1 (and GroupC) chassis since the 58084 kit released in 1990. Would it be "THE" part that solves the Road Wizard F1's motor mount weakness?

I don't know the answer as I am no engineer: I have no idea about the real influence of this part. I just asked myself a silly question while I was thinking to something else ![]() .

.