GT-01 chassis: the slipper

The TamTech Gear series feature something you usually find on racing models: a slipper clutch. As my new model has this feature, I search for information to understand how it works and what it is meant for.

So, the slipper clutch is meant to improve the power transmission to the ground: you generally find it on off-road models. To avoid wheels spinning due to the lack of grip, the slipper absorbs the difference between the power generated by the motor and what the wheels can handle without skidding. In addition, it deals with the opposite function: when landing a jump, the wheels generally don't spin at the speed that would correspond to the real model speed. In the air, there are no grip or weight constraints: the motor can turn full speed. But the motor can also go slower than the real vehicle speed since accelerating or braking while the model is flying will control the chassis angle at landing. So the slipper will absorb the mechanical shock from the landing: without slipper, the gears will have to endure these constraints (stressing the pinion teeth).

The long story short: a slipper clutch is both a traction control device and a gear protection device.

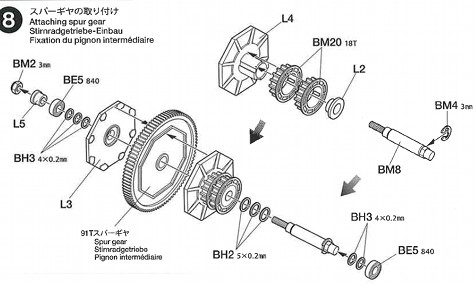

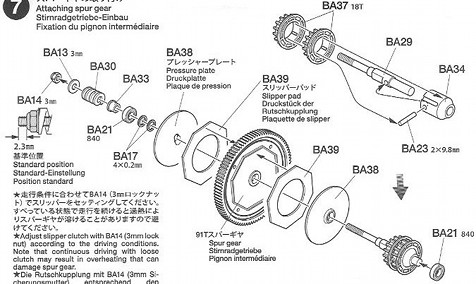

To better understand, here are the assembly instructions from Tamiya DB-01 chassis: no slipper on the left, with it on the right.

What you can see: with the slipper, the countergear is not directly connected to its axle since it is caught between two friction disks ("slipper pad", often teflon-treated). These slipper pads are then pushed against the countergear by two pressure plates which are directly connected to the countergear axle.

How does this work? The easiest way is to consider the 2 extreme slipper setups:

- Overtight slipper: in fact, it no longer serve what it is meant for since the countergear is directly connected to its axle to spin the wheels.

- Loose slipper: the countergear turns but the slipper captures all the motor load. Wheels don't spin so the car doesn't move.

For any intermediate setup, the slipper will work as follows:

- Traction control: whenever the motor gives a violent impulse, the motor pinion will drive the countergear (thus the wheels) but only after a brief slip of the slipper pads.

- Gear protection: when landing a jump, when the rear wheels touch the ground (whatever the grip), their rotation speed is substantially different from the ground scroll. At the moment of contact, the slipper clutch "absorbs" this difference during a fraction of second in order for everything to get balanced. Without slipper clutch, the gears and driveshafts will endure this difference, producing wear or even breaks.

And now, how to setup a slipper clutch:

- place the model on a table and switch it on.

- firmly hold the rear wheels.

- give a brief throttle impulsion from the radio.

Either you hear a slipping sound coming from the gearbox (loose slipper), or the front wheels will lift off the table (overtight slipper). The best base setup will be when the front wheels almost loose contact with the table surface. The best setup will depend on grip condition at the track.

So the slipper is mainly used to protect the gears at landing in off-road categories. The traction control function is normally left to the driver's finger on the throttle command of the radio. This is the reason why the slipper is not allowed in any on-road competition and thus the reason why manufacturers don't install slippers on their on-road models. If Tamiya installed it on their on-road GT-01 chassis, it is only meant to make the chassis easier to control by beginners or unexperienced drivers.

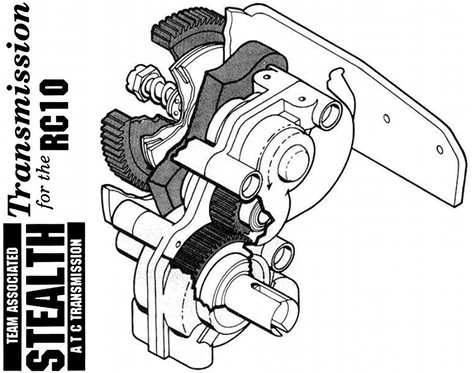

A little bit of history to conclude: the first real slipper clutch is the one found in the Stealth transmission of Associated's RC10 Team Car in 1990, even if Kyosho had previously started with "racing clutch" on their Optima series in 1987. The first Tamiya model to feature a slipper clutch was the Super Astute released in 1991 (called Tamiya Traction Control).

Illustrations from the RC10 Team Car manual. © Associated Electrics, Inc.